Green PeasProcessing Plant

Freezing is increasingly becoming the processing technology of choice for fruits and vegetables around the world. Fruits and vegetables of seasonal nature, with consumption throughout the year are ones with maximum potential for processing. Green peas, with its use in several Indian cuisines, fits these criteria perfectly and hence is now one of the most processed vegetable using freezing technology. India is the highest producer of green peas and also its highest importer In India. This explains the high demand that this processed vegetable commands in the market.

Green Peas Processing Plant

Please Click on The Machine Picture To View It's Details

GREEN PEAS PROCESSING

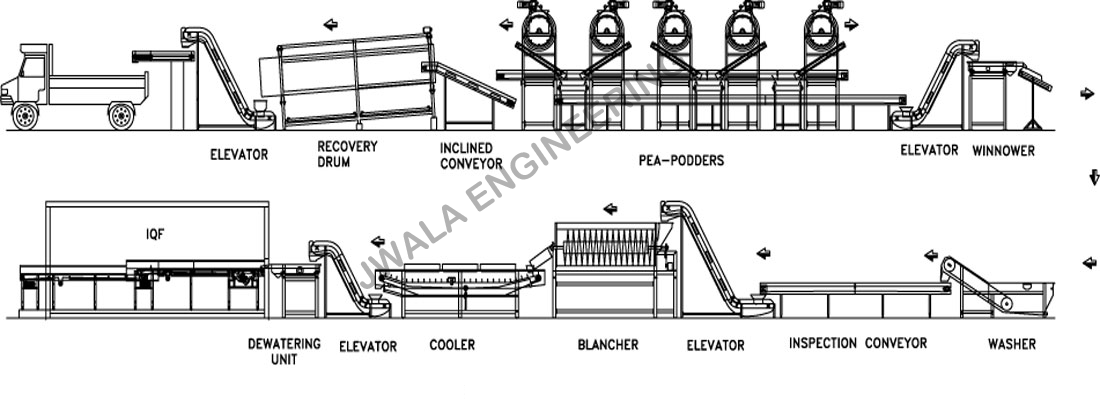

The entire green peas processing line can be divided in the following sections:

PREPARATION

This involves the following operations:Peas Depodder - The raw green peas are fed into a peas deppodding machine where the pea grains are separated from the pods. Raw peas are fed into the pea podders with elevators.

Collection conveyor for peas and waste - The pea grains are collected on a conveyor to feed to processing line and waste is carried to waste processing line.

Peas Winnower - This process separates the whole pods that are not depodded from the grains. Also tiny pod pieces that clog the processing line are separated at this stage

PROCESSING

Vegetable Washer - To wash the product thoroughly before further processing.

Vegetable Blancher - To kill all enzymatic activity by heating the product in boiling water. Blanchers could be of belt type or drum type depending upon the application. Blanching time can be varied to suit different products.

Vegetable Cooler - The temperature of the product is brought down to 10-15 deg C so that cooling in the freezer is easier. Cooler involves passing the product through chilled water for specified amount of time. Chilling time can be varied to suit different products

Dewatering Conveyor - Surface moisture of the product is removed before freezing. This ensures that no ice is formed on the product during freezing and improves efficiency of the freezer. Dewatering is done using vibratory conveyors.

WASTE RECOVERY

Green Peas Recovery Drum - Waste recovery remains recovering pea grains from the waste pods carried along by waste conveyor. Recovery is done using waste recovery drum which involves perforated screen with waffles placed along the length.

Waste Collection Conveyors - Conveyors and elevators are provided so that the waste is dumped directly to the truck or waste carrying van.

IQFFreezing is done in Individual Quick Freezers. The product is fluidized as it moves forward ensuring that every grain of product is freezed properly and the product does not lump together

COLD STORAGE

Storage for the frozen product is done in cold chambers where the temperature is maintained at -18 deg. C. Series of compressors and other chilling equipment are used to maintain uniform cold temperature in the chambers.