Jam Processing Plant

Jam Processing Plant

Jam is a popular form of processed food used for consumption around the world. There is always a good demand for processed Jams. In India as well there has always been a good demand for jams.

In small to mid capacity plants, fruit jam is produced from readymade fruit pulp. In larger plant, jam is produced directly from raw fruit.

Jam Processing Plant

Please Click on The Machine Picture To View It's Details

JAM PROCESSING MACHINE

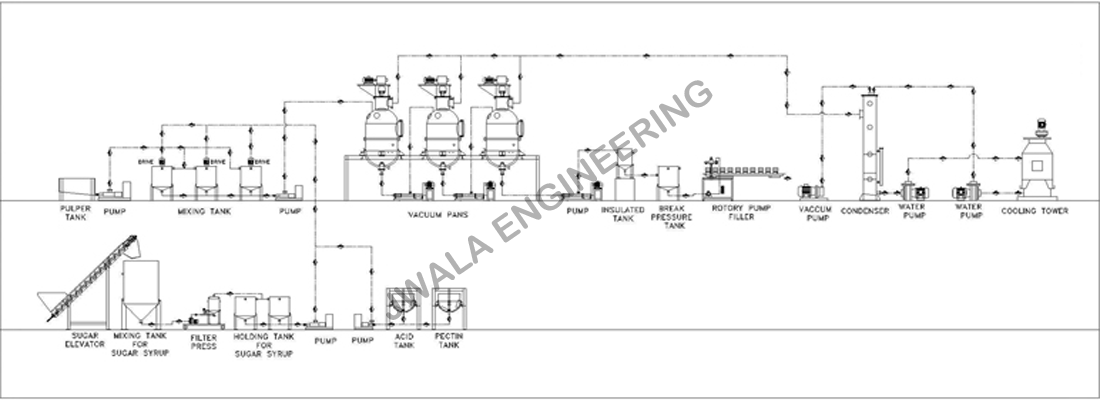

The jam processing machine can be divided in the following sections:

SUGAR SYRUP PREPARATION

This involves the following operations:Mixing Tank - Sugar is fed in the tank with water and the two are mixed along with heating. The mixing takes place in a SS tank with stirrer with scraping arrangement

Filtering Machine - The sugar syrup solution is filtered and stored in a storage tank. The filtration takes place in a filter press

Storage Tank - The filtered sugar syrup is stored in storage tank with stirrer

Dosing Pump - With the help of dosing pump measured quantity of sugar syrup is fed to the jam processing Vacuum Pan

PECTIN PROCESSING

Pectin solution is prepared by mixing pectin powder with water along with heating

PROCESSING

Vacuum Pan - The solution is mixed and heated under vacuum. Concentration is done using Vacuum Pan complete with SS pan with scrapers, condenser, vacuum pump, recirculation pumps, cooling tower etc.

PACKAGING

Jam is normally filled in wide mouthed glass bottles. The following steps are followed:Bottle washing - The bottles are washed thoroughly before filling

Filling - Filling of right quantity of jam in bottles is done in Rotary Pump Filling Machine. The machine can be used for filling in all type of standard can sizes with high accuracy.

Capping - The caps are fixed on the bottles with a capping machine.

Labeling - Labels are applied on the bottles to complete the packaging operations