Tomato Processing Plant

Tomato is one of the vegetables that is processed the most around the worldwide. Tomato puree, tomato sauce and tomato ketchup are part of everyday meals of most people. Hence there is always a good demand for processed tomato products. In India, tomato is grown in good quantity and there is still a lot of potential for tomato processing plant & machine. The common forms of processing machine plant for tomatoes include:

In small to mid-capacity plants, tomato puree, sauce and ketchup is produced directly from raw tomatoes. These processing machine plant can be used for readymade tomato paste as well. Large capacity plants involve making tomato paste to be filled in aseptic drums or cans.

Tomato Processing Plant

Please Click on The Machine Picture To View It's Details

TOMATO PROCESSING PLANT

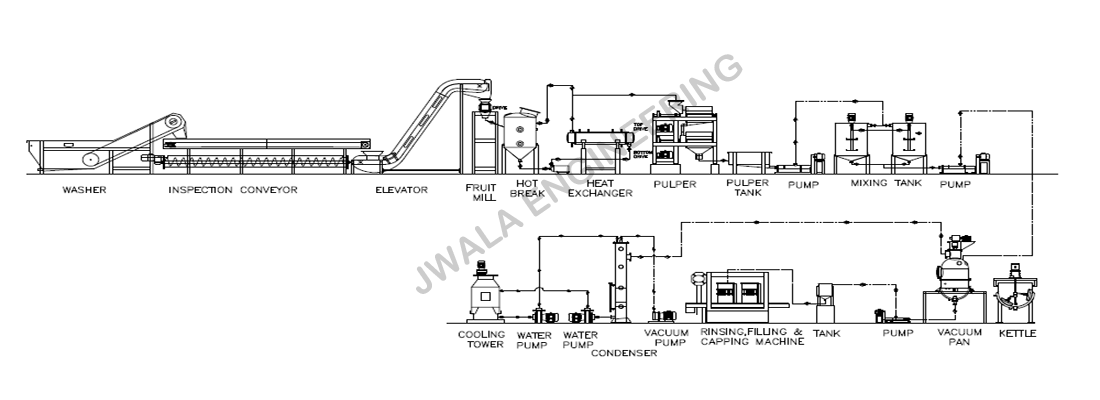

The entire tomato processing plant can be divided in the following sections:

PREPARATION

This involves the following operations:Inspection cum Preparation Conveyor - After washing the product is passed on a 3 lane conveyor where inspection of the product takes place. On this conveyor each tomato is inspected. The waste and improper tomatoes are dumped in discharge chutes. The inspected tomatoes are taken to the next unit with an elevator

PRE-PROCESSING

Hot Break System - This system is installed to retain the pectin, which ensures viscosity and other important properties of tomato, after crushing of tomato in processing plant or machine. The system consists of the crushing machine, closed tank, heat exchanger and high speed recirculation pump interconnected to each other.

The refined tomato juice is collected in a collection tank placed below the unit

PROCESSING

Standardization Tank - The tomato pulp received from the pulping section is standardized for consistency of properties like concentration, sweetness etc. This is especially useful in preparation of tomato sauce ketchup as spices, salt and other ingredients are added to the tomato juice at this stage itself and this determines the final taste of the ketchup prepared. This is done is SS tanks with stirrer mounted on it.

Vacuum Pan - The tomato pulp is concentrated under vacuum. Depending upon the level of concentration different outputs are obtained, for e.g. Tomato puree at 9-12 deg. brix, tomato paste at 28-32 deg. brix. Concentration is done using Vacuum Pans or multi effect evaporators.

Pasteurizer - The concentrate is pasteurized by heating it at high temperature for specified amount of time. Pasteurization is done in scrape surface pasteurizer or tube in tube pasteurizer depending upon the capacity of the machine plant.

We are manufacturers and suppliers of tomato processing machine, tomato processing plant, tomato ketchup processing plant, tomato sauce processing plant, tomato puree processing plant and machine in Mumbai, India.