Mango Processing Plant

Mango is called the king of fruits. There is a large market for mango fruit around the world. Since mango grows mainly in tropical climate there are only a few countries that grow mango in good quantity. India is the largest producer and exporter of mangoes in the world. Processed mango is also exported in huge quantities from India. So naturally processing of mangoes is a big industry in India. The common forms of processing machine plant for mangoes include:

Of the above, mango pulp is the most common form of mango processing and also has the maximum demand and export potential. Canned mango pulp is preferred for small to mid-size plant whereas in higher capacity machine, aseptic filling is given preference.

Mango Processing Plant

Please Click on The Machine Picture To View It's Details

PROCESSING OF MANGO PULP

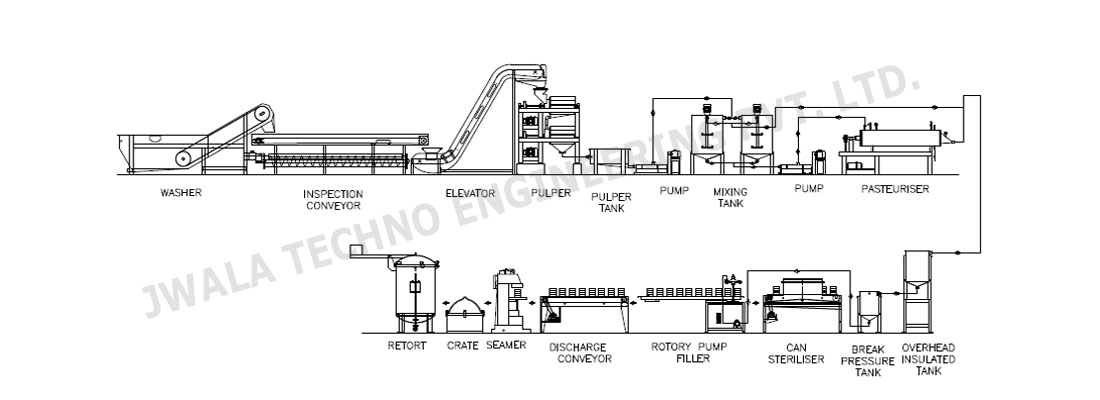

The processing of mango pulp can be done in different ways, with Canning and Aseptic filling being the prominent ones. However, whatever the processing technology followed, the mango processing plant can be divided in the following sections:

PREPARATION

This involves the following machines:Mango Washer Machine- The raw mangoes received are fed in a hopper / conveyor from where the product is fed into the Washer. The mangoes are thoroughly washed in this unit due to agitation in water with the help of blower. After washing the product is taken to the next unit with the help of a take-off elevator attached to the machine. Washing can be in single stage or two stages depending upon the requirement.

PULPING

Destoner - The separation of the stone and skin and basic extraction of fruit pulp happens in this unit. The stone and skin are removed from the other end through a discharge hopper and the fruit pulp is collected in a pulp collection tank placed below this processing plant.

Pulper cum Refiner - The pulp received from destoner is further refined in two stages with progressive decrease in sieve size of the machine. The refined pulp is collected in pulp collection tank placed below the unit. In smaller capacity plant the prepared fruit is directly fed in processing machine rather than passing through the destoner

PACKAGING

Depending upon the processing technology used, packaging type differs. For Canning line, packaging is done in tin cans. For Aseptic filling, the pulp is filled in drums of large sizes. The following processes are followed in canning line:

Can Reforming Machine - The tin cans are normally available in flattened form and have to be formed in its final shape using a series of can forming machines.

Can Sterilizer - The can are sterilized by passing it through steam for specified amount of time in the Can sterilizer.

Mango Pulp Filling Machine - Filling of right quantity of pulp in cans is done in Rotary Pump Filling Machine. The machine can be used for filling in all type of standard can sizes with high accuracy.

Can Seamer - The closing lid is placed on the filled cans are they are seamed on the Seamer machine.

Canning Retort - The seamed cans are placed in crates which in turn are placed in retorts. Steam is passed in retorts for some time so that the cans are completely sterilized and can be stored in room temperature for long periods of time.

We are manufacturers and suppliers of mango pulp processing plant and machine in Mumbai, India.